ZKW is developing a complex projection technology for headlight systems, changing illumination dynamically. It is based on the individual control of a high number of LEDs, which are placed in a specific geometric order. Each of the LEDs has its own specific illumination space, and the combination of all spaces results in the whole light distribution.

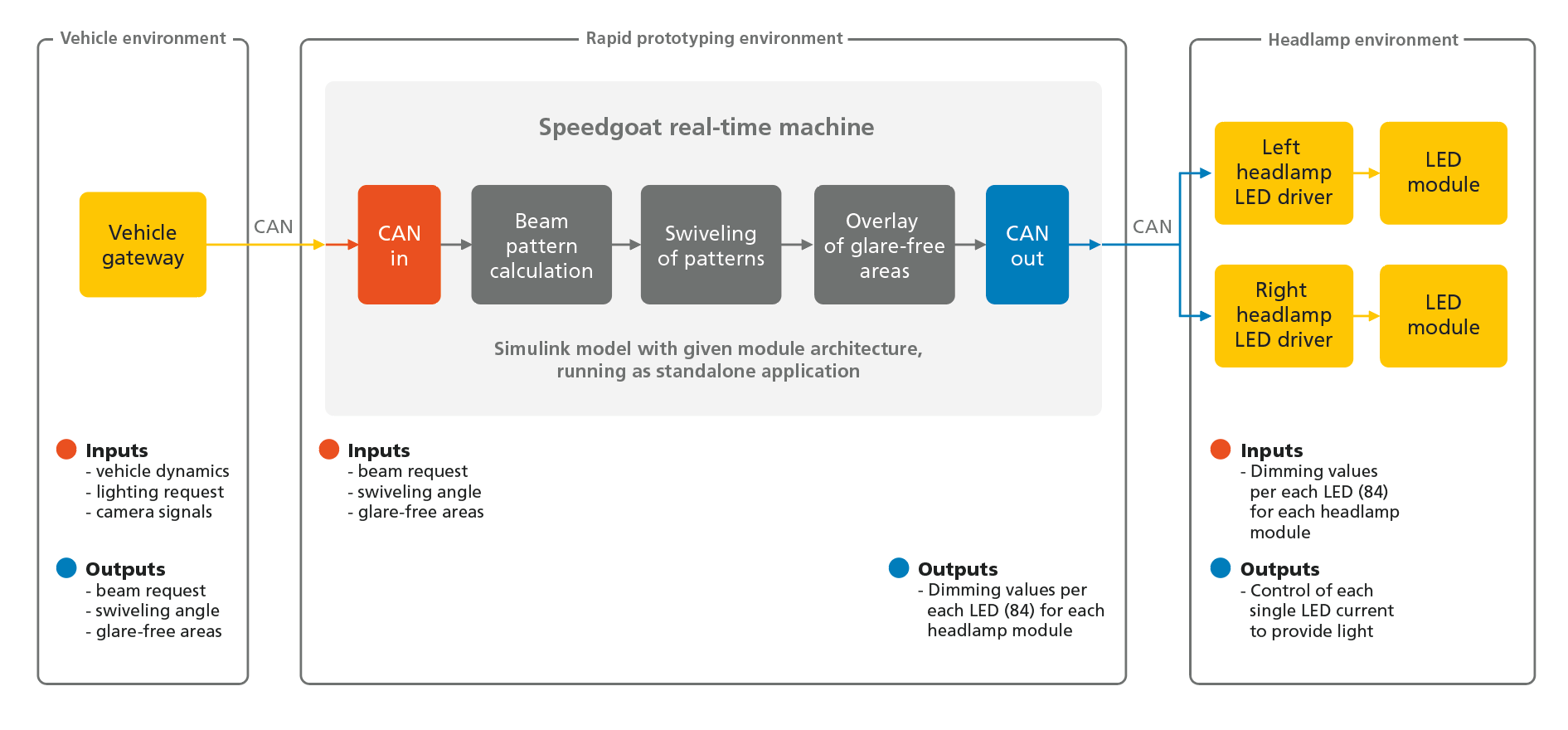

This technology for headlight systems enables the functionalities needed for an adaptive driving beam containing an advanced front lighting system (AFS) and a glare-free high beam (GFHB). Also, a bending light is possible by dynamic control of the LEDs, which emulates the mechanical swiveling of the whole light distribution. All software algorithms, structured as flexible modules, are eventually running on an ECU placed outside the headlamp. Core software modules are used for controls and to perform low-level tasks such as interfacing with all the LEDs.